Diamond Pulley Lagging

Troughed Pulley Conveyors

Pulley Lagging

Introduction

Lagging is the term used to describe the application of a coating, cover or wearing surface which is sometimes applied to pulley shells.

Lagging is often applied in order to extend the life of the shell by providing a replaceable wearing surface or to improve the friction between the belt and the pulley. Notably drive pulleys are often rubber lagged for exactly this reason.

This section provides some useful information regarding the different types of lagging as well as some technical details and recommendations for lagging of pulleys.

DIAMOND PULLEY LEGGING

Rubber lagging is applied to pulley shells in order to improve the friction between the pulley and the belt.

Conveyor drive pulleys are often supplied with diamond grooved lagging as indicated in the adjacent sketch.

‘Diamond grooved lagging’ refers to the pattern in the lagging and this pattern, like with vehicle tyres, enhances the grip or friction even if the belt surface is dirty.

Lagging Specifications

Rubber pulley lagging is usually specified in terms of its type, hardness, thickness and finish as follows

b) Lagging Hardness

The hardness of the rubber lagging to be used on a conveyor is generally dependant on the pulley location.Pulleys which come into contact with the dirty- or carrying-side of the belt including snub pulleys and bend pulleys, usually employ lagging with a hardness of 35 to 45 Shore ‘A’.Drive, take-up and tail pulleys should use lagging with a Shore ‘A’ hardness of between 55 and 65

c) Lagging Thickness

Rubber lagging thickness varies extensively. Commonly used lagging thicknesses are as follows Drive pulleys, grooved lagging

Other pulleys, plain lagging

a) Correct operation of the conveyor

Notwithstanding the above, it is possible to achieve the optimum life from pulley lagging by observing the following basic pointers Ensure that a conveyor’s take-up unit applies the correct load to the belt to prevent belt slip on the drive pulley(s) on startup.Do not attempt to reduce belt slip by throwing sand or similar material into the pulley feed/nip point. This accelerates wear of the lagging.Do not over-fill the conveyor as this will necessitate additional torque to start and run the belt, which may result in belt slip over the drive pulley.Install and maintain a belt plough on the return belt, immediately ahead of the tail pulley. This will minimise the opportunity for lumpy material to be trapped between the belt and pulley, which results in localized damage to the lagging and belt.Ensure that pulleys are correctly aligned so that the wear pattern is uniform across the pulley.In the case of screw take-up units, ensure that the take-up is correctly adjusted to provide adequate belt tension under all operating conditions.Prevent or address material spillage onto the return belt so that pulleys are in contact with a clean belt as far as possible.Install and maintain belt scrapers to minimise material carry-over, which is deposited onto bend and snub pulleys.If a drive pulley continues to slip on startup for no apparent reason, consult the designer to confirm the conveyor design parameters and start-up philosophy. Do not ignore the slippage!

a) Lagging Type and Finish

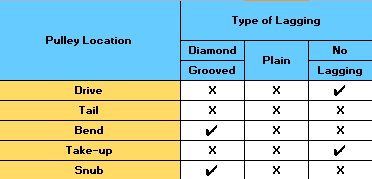

The type of lagging to be used is specified on the basis of the application, duty and required life of the lagging as outlined above.In general, the type of lagging used on troughed belt conveyors is indicated in the table below

Ceramic-type lagging is not usually applied to troughed belt conveyor pulleys, neither is strip lagging.

3. Useful Tips for the Care and Maintenance of Pulley Lagging

Like all equipment, the life expectancy of rubber lagging is dependant on the operational environment, the quality and frequency of maintenance and the manner in which the equipment is used.

b) Correct design and component selection

The designer should ensure that the correct pulley diameter is used so as to prevent over-stressing of the belt and lagging.Select the appropriate type and hardness of lagging to be used depending on whether the pulley is a drive, tail, take-up pulley and so on.Use grooved lagging on drive pulleys which assists with traction, expels moisture and is less likely to slip when dirt has become trapped onto the return belt.Follow recognized conveyor design procedures and equipment sizing guidelines when designing a conveyor

c) Maintenance measures

Inspect and monitor the condition of pulley lagging regularly.Repair local damage to lagging before the damage propagates to other areas.Ensure that re-lagging of pulleys is done by experienced personnel to maximize the useful life of the lagging.Make a spare pulley available so that a damaged pulley, or damaged lagging can be removed from service and rectified or refurbished correctly and in a controlled environment.

.